Full-cycle manufacturing company

in the field of polymer products

We offer effective solutions based on deep market knowledge

and significant manufacturing experience:

- We are 30 years old;

- Modern production equipment;

- Highly qualified staff;

- Quality control on each stage;

- We guarantee production and delivery terms.

The company continues to develop dynamically due to modern technological solutions

Introduction of Kaizen philosophy at the factory showed the ways of improvement and further perfection of production

All the company’s products are environmentally safe and quality, we are responsible for quality control at all stages of the production process

About company

![]()

Trade — Information Service — is a full — cycle manufacturing company in the field of polymer products in various industries, has existed since 1995. The company offers a product of European quality of its own production using advanced technologies. We choose a creative approach to tasks solving, develop new products and improve service quality. We do our best to improve constantly the qualification level of our employees.

The production potential of the company also includes own laboratory, logistics, own development and highly qualified personnel, engaged in constant improvements in Kaizen style and being able to find the solution of the task in optimal time.

We are able to create!

1 day

from 2 days

from 2 days

from 80 days

from 4 days

APPLICATION FOR A FREE CONSULTATION:

Plastic processing plant: a full cycle rate

Plastics plant “TIS”: list of services and product offers

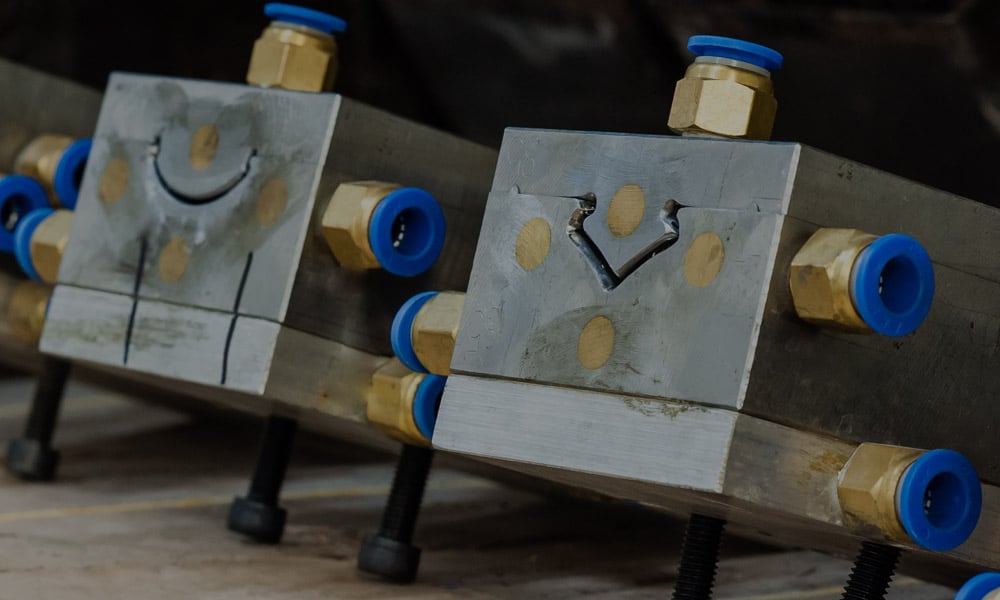

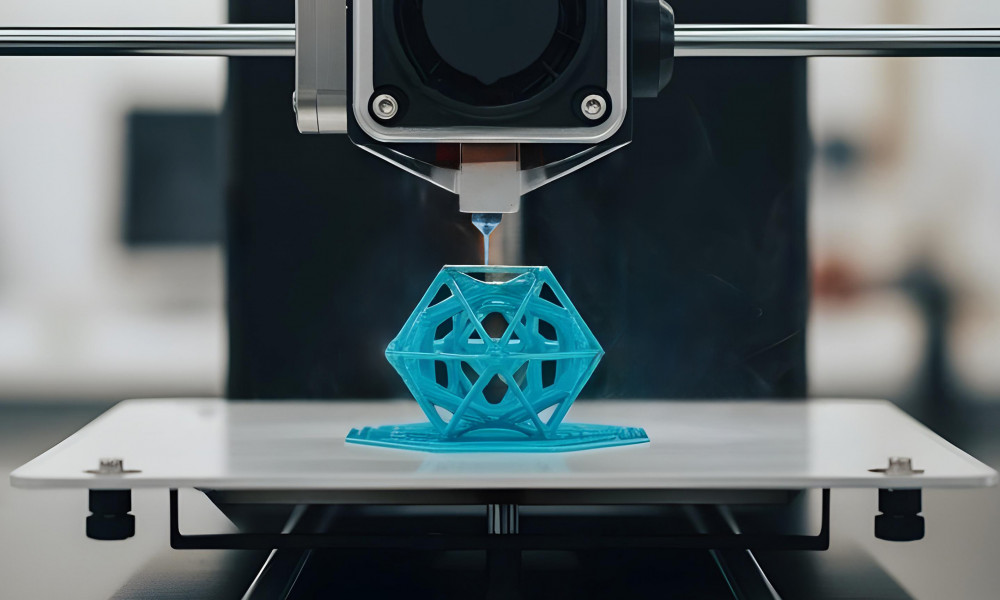

- Polymer casting

- Polymer extrusion

- Design and Design

- Lab tests

- Providing advice

Modern equipment and staffed: valuable resources of the enterprise

For more detailed information send a request or call:

+38 (066) 251 05 80, +38 (044) 251 05 81, +38 (044) 251 05 82, +38 (044) 251 05 83,