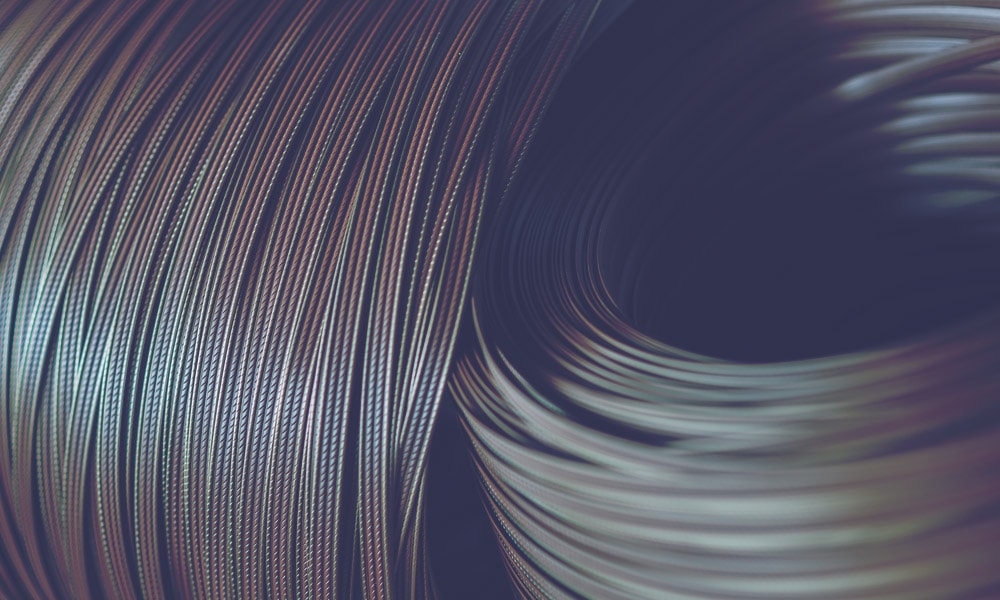

Extrusion molded products

With extrusion, molten polymer material is forced through an extruder head in a continuous process, thus acquiring the necessary forms and geometric parameters of the product, then the product is cut to the desired length.

With this method we can obtain profiles, loops, tubes, seals and many other products. Products can be monolithic and foamed.

The main line of polymers that are processed by extrusion:

Polymer extrusion is a multi-level manufacturing process that results in molded products with the desired cross section. These are profiles, seals, pipes, loops, other products with a foam and monolithic structure. The method has a continuous format. It involves the extrusion of a preheated plastic to a viscous consistency through a molding tool.

Due to the fact that the chemical composition of the raw materials and the final product are identical, the technologists of the company “ Information and Trade Service ” guarantee the high quality of each product. They manage to achieve compliance of manufactured products with accepted quality standards by resorting to the minimum extruder settings. The production line also assumes the presence of special extrusion tools and auxiliary machines, whose well-coordinated work allows us to produce solid batches of products as soon as possible.

Polymer Extrusion: Basic Processes

Production of polymer products in the shops of the company involves a number of operations. Functional equipment is used by technologists and engineers of the plant to heat, plasticize, homogenize raw materials, give it the desired shape. The processes occur under the influence of high temperature, moisture and direct mechanical action.

Variable parameters – the humidity and composition of the processed raw materials, the pressure exerted, the temperature, the duration and intensity of the impact on the material are determined by the employees individually. They select the optimal conditions for processing and molding each type of raw material - polypropylene, PVC, polycarbonate or polyethylene.

Plastics extrusion in the workshops of the company "TIS": benefits and guarantees

Customers from Kiev and other cities of Ukraine who are interested in plastic extrusion, choose cooperation with the company “TIS”. Customers rely on the following plant benefits:

- A wide range of services provided

The company's production facilities, represented by its own laboratory, equipped with workshops and molding lines, allow us to provide services for the production of various polymer products.

The extrusion of plastic profiles and other products will satisfy all customers' expectations. Due to careful following of technology, products have clear geometrical parameters and the necessary forms. After production and quality control, it is cut to the required length, packaged in a container, then delivered to the destination agreed with the customer.

- Providing advice

As part of the purchase made by the company, customers will receive competent detailed advice. Plant employees will help you find the best ideas, offer ready-made solutions, talk about ways to reduce costs and improve the performance properties of the polymer products created.

- Universality of method

The extrusion method is widely used for the production of plastic products, since it is famous for its versatility. With the help of technology, it is possible to recycle any kind of polymers – thermoplastics, thermoset plastics, elastomers.

![]()

For more detailed information send a request or call:

+38 (044) 251-05-80, +38 (044) 251-05-81, +38 (044) 251-05-82