Polyethylene

Thermoplastic polymer hydrocarbon; Solid, colorless, lighter than water. It is one of the most common and safest polymers in the world. Used for the production of materials and products for packaging — film and plastic bags, containers (bottles, jerricans, etc.), pipes production, and also used for the production of artificial rattan.

Extrusion of polyethylene is used to create packaging film, the production of plastic bags, containers, tanks, pipes, and artificial rattan. The method is common due to the fact that one of the safest, affordable, and common polymers is used as a raw material. Polyethylene has no color, is lightweight and has decent strength.

Specific features of the production process

Under the influence of moisture, high temperatures and mechanical effort, a complex physico-chemical process occurs. To start it requires the availability of appropriate equipment. In the company “TIS” The workshops are equipped with powerful functional extruders in which granulated polyethylene is heated to a viscous consistency. The resulting mass – This is the basis of future products. It is passed through the holes to give the desired shape, and then cooled. As a result, it is possible to fix the result, to avoid crystallization.

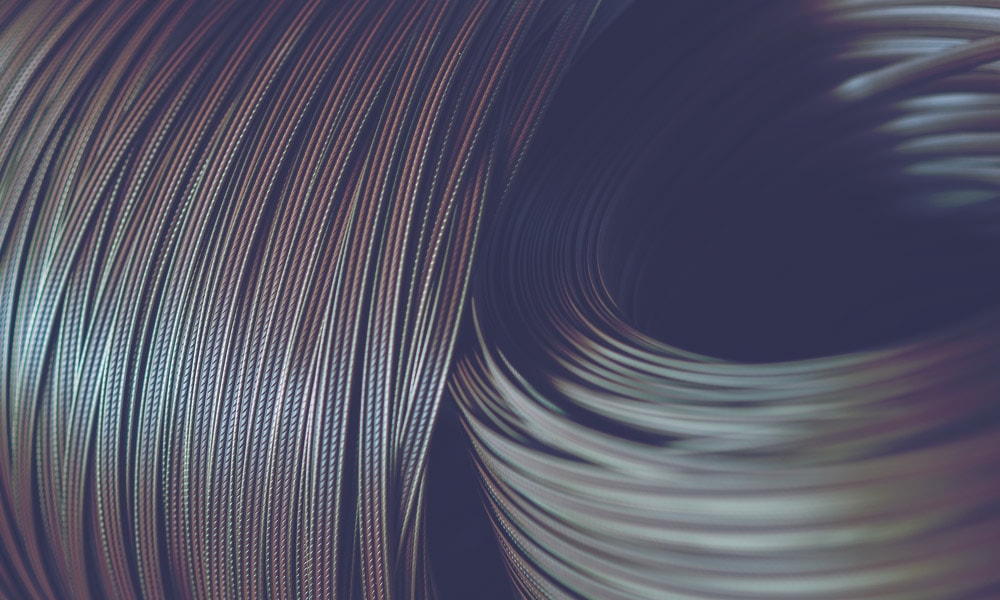

Polyethylene extrusion production line

The method requires an equipped production line. It consists of the following nodes:

- Transporter;

- control panel;

- folder and knives;

- blow molding machines;

- bootloader;

- winder, etc.

Line configuration may vary depending on the tasks. Before starting, the equipment is carefully checked, adjusted and adjusted. Employees of the shop ensure that the devices used work properly and harmoniously.

Extrusion of polyethylene from the company "TIS": list of benefits

By purchasing products to order, customers of the plant receive favorable terms of cooperation. The purchase provides access to the best prices in Ukraine, fast deliveries to Kiev and the regions, and detailed advice from experts. Starting interaction with the supplier is worth other reasons:

- No defects in delivered batches

Custom-made polyethylene is extruded under the strict control of technologists. Therefore, in the delivered batches of products there are no samples with defects or defects. Employees of the company carefully select the variable parameters for the processing of materials, so that the result was perfect. Prevents the problem of film thickness variation, tarnishing of the surface, insufficient strength by adjusting the equipment and careful selection of modes of its operation.

- Timely equipment maintenance

The company's production facilities are comprehensively serviced during maintenance. The extruder heads are cleaned from carbonation and polished in a timely manner, the screw rotation speed is adjusted in accordance with the specifics of the operations performed.

- Bid on quality raw materials

For processing, we select selected polymeric raw materials that are stored in special conditions. Before entering the extruder, granulated polyethylene is tested for compliance with quality standards and dried to the desired moisture values.